Towel Loom

HY-JT airjet towel loom adopts reed motioning looping system drivenby servo motor which can adjust loop height 0-14mm, and can weavelong & shortloops and wave loops, Every weft can be made in differentloop height. Loopcycle can be set within 3-9 repeats. With infinitelyvariable loop height andhighly uniform in terry, top grade towels withrich textu re can be woven easily.

PRODUCT DESCRIPTION

· Intelligent And Humane

To satisfy the demands of future towel factories, HY-JT adopts the desians meeting humanengineering, whichmakes the operation of each part easy and convenient.HY-JT is also loadedwith latest electronic controtechnology ~ communication and internet technique, such as maincontrol computer, colored multi-functionpanel, so that remote control, high intelligence andhumanization,high efficiencyin weaving are available.

· Electronic Let-offAndTake-up

Electronic let-off and take-up are standardized device inHY-JT weaver's job is much simplified. The weft density isset byelectronic,needless to use weft density cone. Withexact weftdensity setting, best weft weight and least weftyarn consumptionare realized,Furthermore, this settingcan apply to other looms.

Electronic let-off is driven byindependent auxi.motorand tensionis controlled by electronic sensor. To preventthe starting marks.whether the beam is full or idle, thissystem should be runningaccurately.And,electronic take-up is also driven by independentmotor. Weft density canbe set within 6~134 picks/cm.Accuratesystem canprevent starting marks.

· High Efficiency Stopping Device

HY-JT holds efficient electronic functions in loom stops due toweft breakwarp break, selvage yarn break, etc, Stop cause showsthrough displayscreen and multi function 4-color lights.

· Electronic Weft Cut-off Device

Electronic weft cut-off device running along with reedseatisequippedin HY-JT,which can better control weftcut-off angle andprevent selvage defects.

· Variable Looping Mechanism

Looping cycle can be freely set between 3-9 repeats;infinitely adjustment available in0~14mm looping height.Simple loopingcycle can also be set, With this mechanism.itbecomes easytomake towel designs, and convenient tochange different sorts oftowels.

(1)Loop height is up to 14mm( Max.12mm in this industry)

(2)Looping height can be adjusted infinitely, accuracy ofwhich is 0.1mm.

(3)Severalloopingheightin one fabric is available; waveloopingjacquard fabrics can be made

(4)Highlevelautomation and steady tension control enableHY_JT to weave top grade towels.

· Stable And Reliable

Through 3-D design and computer interpretation,mechanical frames of wall boards andbrams aremade to best advantage, weft beating up becomes much less in weight andmuch better inbalancethuslow vibration is maintainedin high speed running

· Stable Support For High Speed Weavtng

The body of HY-jT air jet towel loom is made of two cast iron wall boards which are connected by severalstrong beamsEccentric rocking shafts with little moment of inertia are adopted. New designed tenaciousframework and well balanceomechanical parts greatly decrease vibration. Continuous high speed running isthus realized: the loom is enabled longand stable,less vibration,high speed,low noise.

· More Stableln WeftInserting And Beating-up

Accurate numerical control is adopted in HY-jT for weft inserting. Opening and closing time ofelectromagnetic valve iscounted in milisecond, High sense electromagnetic valve, quick in response, canrapidly transfer the control signal tooutput airstream, Both stability and reliability of the weft insertion svstemare improved as the space between auxinozzles is narrowed down. Whole piece of steel reed andconnecting links are installed in HY-JT to ensure strong weftbeating up. Within the range of reed, weftbeating up is tightened, high density weft weaving is enhanced.

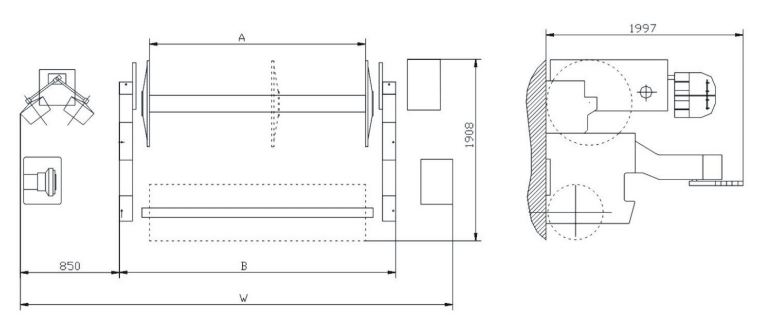

Dimension Figure

|

Reed Space (cm) |

190 |

210 |

230 |

280 |

340 |

360 |

390 |

|

A |

1900 |

2100 |

2300 |

2800 |

3400 |

3600 |

3900 |

|

B |

2540 |

2740 |

2940 |

3440 |

4040 |

4240 |

4540 |

|

W |

4355 |

4555 |

4755 |

5255 |

5855 |

6055 |

6355 |

Reed Width(cm):

190.210.230.260.280,340.360

Yarn Count Range:

Short Fibre:5s/-100s/1

Filament:20D1600D

Weft range:

Weft selection available in two nozzles

fournozzles,sixnozzles,eightnozzles

Shedding mechanism

Electronic Dobby

Electronic Jacquard

Cam Shedding

Motive Power:

Three-Phase asynchronous Motor:

Button start,stop,forward andreverse,slow motion

Electromagnetic clutch fixed position stop:

Wefting insertion:

Energy savingmain nozzle+swing main nozzle

Energy saving profiledreed;

Energy saving secondarynozzle,

Warp let-off.

ELO electroniclet-off:

Upper andlower beam with auto reverse

fun cti on ;

Weft shearing:

Independent electronic shearing

Stopping device:

Weft broken :photoelectric reflex weft detectin g

Cracked ends:by electrical contact rod;

Others; leno selvage yarn breaks

Stop cause display:screen show.

Multifunction 4 colors lights;

Automation :

Control:multifun ctionmicrocomputer contro

system,available in parameter

setting/control/monitoring/auto diagnosis/manua

Pick finding:automatic searching for sheddingJoggingthrough converter(forwrd and reverse

Other:output terminal of monitor

Waste edge:electronic leno.

Recommended Products

OEM/ODM Processing Services

Here, we provide a convenient online inquiry service. You only need to briefly fill in the following information, and our sales team will provide you with a detailed quotation within 24 hours.

Whether your needs are a single product or a complete set of customized solutions, we will provide tailored quotations and technical support according to your specific requirements.

GET A CUSTOMIZED QUOTE

Here, we provide a convenient online inquiry service. You only need to briefly fill in the following information, and our sales team will provide you with a detailed quotation within 24 hours.

Whether your needs are a single product or a complete set of customized solutions, we will provide tailored quotations and technical support according to your specific requirements.