Air Jet Loom

The strong and tough frame is formed by the new wallboards atboth sides and 4 pieces of cross beams. The middle supportsunder the beams have further strengthened the vibrationresistance and the heavy machine body has laid asolidfoundation for the machine with the high speed and low noise.

PRODUCT DESCRIPTION

· High Speed Adaptability

· Box-type Wallboard Structure

The strong and tough frame is formed by the new wallboards atboth sides and 4 pieces of cross beams. The middle supportsunder the beams have further strengthened the vibrationresistance and the heavy machine body has laid asolidfoundation for the machine with the high speed and low noise.

· Unified Lubricating System

Main transmission parts (Casing Parts) is lubricated by oil bathand others are lubricated by centralized oil-supplying system.Automatic oil-supplying device can automatically lubricateequipment by the instructions on display

· Main motor Direct drive motor (Optional)

Successfully used direct drive technology of new energy vehicle on HYCDairjet loom,achieved progressive improvement. Weaver can adjust thefunction of multi weft density and speed in touch screen. The rotor of directdrive motor is made of permanent magnet material, so there is no rotorresistance and hysteresis loss in normal operation. Therefore, the motorhas high efficiency, large starting torque and obvious energy saving effect.

· Beating-up Mechanism with High Speed Adaptability

Narrow Fabric Loom adopts 4-bar linkage beating-up mechanism withhigh speed adaptability.lt has short beating-up stroke and smallvibration when it runs at high speed so that it can beat up forcefullyand steadily.

Broad Loom adopts 6-bar linkage beating-upmechanism with longerpost-center stillness time in order to improve the steady weft running.

· Extensive Product Compatibility

· Multiple Shedding System

Crank Shedding:4 /6heald frames (Optional)Suitable for plain weave with high quality

· Positive Cam Shedding

Max 10 heald frames

Suitable for plain, twill and satin weave, especially for heawy. broad loom.

· Dobby Shedding: Max 16 Heald Frames (Optional)Suitable for versatile plain, twill, satin and smaljacquard weave with high additional value.

· Jacquard Shedding (Optional)

· Airjet tuck in device, suitable for smooth selvage fabric. Different tuck in part with different width. nermally 10mm

· Stable Cloth Fell

It's easy to install and take down the in-headtemple loom with raked cloth fall as it adopts upto down pressing way. The cloth-leading boardand the front end of temple bar are inserted intothe air-conducting part of steel reed, so it'sconducive to the stability of cloth fell and moreobviously effect can be achieved when it isapplied for warp weave, double weave, jacquardweave and high density weave.

· Optimization of Beating-up Angle

Computer simulation analysis optimizes the beating-upangle and stroke angle B,and enhances the beating-upforce to make it more suitable for weaving thick and heavyfabric.

· Perfect Anti-stop Mark System

· Electronic Let-off and Take-up Control Model

Both electronic let-off and electronic take-up are drivenby AC servo-motor to guarantee the balance of the warptension based on real-time testing and feedback. Thejoint operation of electronic let-off and take-up makes themachine-operation easier too.

· The Set-up of Stop and StartAngle

According to the kinds of weaving fabric and the status ofstop mark,the angle of stop and start can be randomlyset up.

· Double Back Rest Device

The application of double back rest is conducive tokeeping the warp wrapping angle always the same. lt hasnothing to do with the size of weaving shaft and makes thetesting of warp tension force easier and more accurate.

· Sing Weft insertion Function

When starting, the loom doesn't beat up weft and candirectly put weft when the yarn block needle is lifted so asto avoid stop mark of heavy twill weave.

· Cloth Fell Follow-Up Model

When the loom stops, the cloth fell moves forward andmake the steel be unable to beat it, Before the loom is onthe cloth fell automatically return and the loom normallystarts.

· Simple and Flexible Operation

· Design of Low Machine Body

HY has improved the height and longitudinal depth of the machine, shortened thedistance between operators and reduced their labor intensity.

· Out-mounted Loose Warp Device

As it adopts out-mounted loose warp device, it makes the deviation adjustment easier.

· Energy-saving,Safe and Networked

· Reduction of Air Consumption

One electromagnetic valve controls two assistant nozzles to makethe air jetting more forceful. Because of the application of shortassistant jetting space, it can guarantee the stability of weftinsertion even though the assistant jetting press is low, Moreover,breast beam serving as assistant air pocket shortens the distanceof weft feeding of assistant nozzles and reduces the loss of airpressure in the process.

· Infrared Safe Protective Feeler

The application of infrared safe protective feelerimproves the safety of operators.

· Production Management Centralized Networking (Optional)

The system can automatically gather and deal with the productioninformation of air-jet loom so you can timely grasp the runninginformation and statistics of loom workshop.

Product Configuration Table

|

I t e m s |

Specifications |

O p t i o n s |

|

|

Reed Space |

Nominal Reed Space |

150,170,190,210,230,280,340,360 |

|

|

Useful Reed Space |

Nominal Reed Width -0~60cm(150~250cm) Nominal Width-0~80cm(above 280cm) |

|

|

|

Weaving Range |

|

Short Yarn:Ne100Ne5 |

|

|

Long Silk:20D1000D |

|

||

|

Weft Selecting |

|

2,4or 6 Jetting-Selection |

|

|

Power |

Starting Way |

Super Starter Motor |

|

|

Directly control and position stop through electromagnetic brake |

|

||

|

Slowly start by frequency converter(clockwise/anticlockwise) |

|

||

|

Operate in both hands through buttons and switches |

|

||

|

Rated Power of Motor |

2.7kw,3.0kw,3.7kw,7.5kw(Jacquard Shedding) |

|

|

|

Weft Insertion |

|

Main Nozzle,Assistant Main Nozzles together with assistant nozzles |

Extended Nozzles |

|

Abnormal Reed |

Energy saving technology for warp insertion | ||

|

Auto-contro of Weft Insertion |

|

||

|

Length Measuring Weft Feeder |

Electrically-Controlled Weft Feeder |

ABS Weft Insertion Brake |

|

|

Shedding |

|

Crank Shedding:4 or6 Heald Frames |

|

|

Positive Cam Shedding:Max.10 Heald Frames |

|

||

|

Electronic Dobby Shedding:Max.16 Heald Frames |

|

||

|

Jacquard Shedding |

|

||

|

Let-off |

|

Double Back Rest Electrically-Controlled Let-off(Single Beam) |

Double Wrap Beams |

|

Negative Loose Warp or Positive Loose Warp |

|

||

|

Flanges Diameter |

800mm,914mm,1000mm |

|

|

|

Take-up |

|

Eelectronic Take-up |

|

|

Max.Take-up Diameter |

600mm(Cam,Dobby,Jacquard Shedding)520mm(Crank Shedding) |

|

|

|

Weft Density |

14-300 pieces/inch |

|

|

|

Cloth Length |

Keyboard display(Meter,Yard)with the function of length-control and stop |

|

|

|

Temple |

In-head |

Underneath |

|

|

Beating-up |

|

The beating-up mechanism with crank multi-reed holders |

|

|

4-bar Linkage Beating-up,6-bar Linkage Beating-up |

|

||

|

Weft Frame |

|

Floor 4 Cheeses(2Jetting Selection).Floor 8 Cheeses(4Jetting Selection).Foor 10 Cheeses(6 Jeting Selection) |

|

|

Leno |

|

Planetary selvage device |

Midspit Width Leno |

|

Waste Selvedge Trimming |

|

Waste Selvedge takes up 2 rollers |

|

|

Weft Cutting |

|

Mechanical Scissors |

|

|

Lubrication |

|

Main transmission parts are lubricated by oilbath and manually-centralized oil-supply |

Automaticaly centralized oil-supply |

|

Stop Device |

Weft Stop |

Photoelectric Weft Feeler with double detect heads |

|

|

Warp Stop |

6-line Warp Stop Sheet |

|

|

|

Others |

Dropper stop for Leno Ledge and Waste Selvedge |

|

|

|

Stop Cause Display |

Information shows on display screen with 4 color stop indicators |

|

|

|

others

|

|

Control:Multi-functional Microcomputer Control System with Parameter Set-up. Controlling,Monitoring,Self-diagnosis and Artificial Intelligence Interface |

Centralized networking (remote monitoring of weaving information) |

|

Broken Weft Searcher:Automaticaly Search Shedding |

|

||

|

Automatic Jetting Control |

|

||

|

Infrared Safe Protective Feeler |

|

||

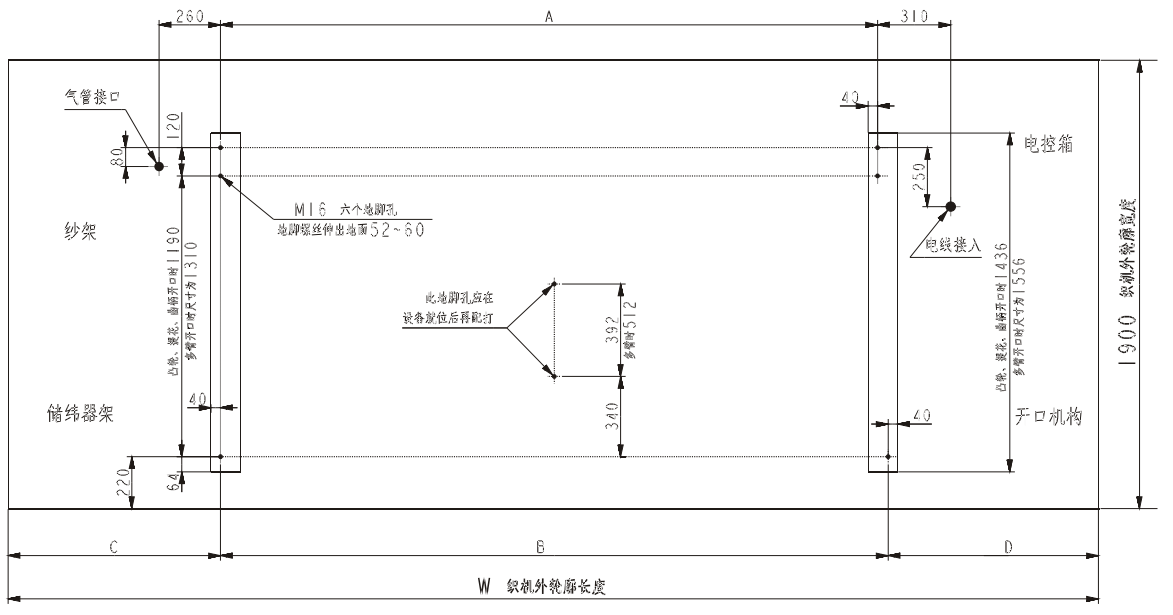

Dimension Figure

· Please keenly note that the provided equipment maybe slightly different from the sample due to differentclient's configurations or design revisions.

|

|

|

|

|

|

Recommended Products

OEM/ODM Processing Services

Here, we provide a convenient online inquiry service. You only need to briefly fill in the following information, and our sales team will provide you with a detailed quotation within 24 hours.

Whether your needs are a single product or a complete set of customized solutions, we will provide tailored quotations and technical support according to your specific requirements.

GET A CUSTOMIZED QUOTE

Here, we provide a convenient online inquiry service. You only need to briefly fill in the following information, and our sales team will provide you with a detailed quotation within 24 hours.

Whether your needs are a single product or a complete set of customized solutions, we will provide tailored quotations and technical support according to your specific requirements.