Rapier Looms

Zhejiang Haiying intelligent Science And Technology Co., Ltd researches to use new technolog)to increase valuentextieindustrvto havecustomermaking better products economically HY9000hiah speed rapier loom wasdevelopedjustonthisconcept.Thismodel machines have some unigueadvantages including high efficiency humanized design,strongbeatingstrengthexcellent stabilityat high speed, advanced electrical control, easy operation and so on.HY9000 topgraderapierloomshaveall the advanced functions. Beating devices are designed onthe oom support beamtherigidityand balanceisincreased a lot, looms can run higher efficiency,less power consumption and stable.

PRODUCT DESCRIPTION

· Double Back-rest & Take-up Roller

HY9000 equips with double back-rest and doubletakeup roller as standard specifications, with this designit can weave high quality heavy fabrics. Two rollers aredesigned as module, it can be removed easily whenweaving light fabrics.

· Adjustable Weft cutter Stable Temple Structure

Adopts more reasonable weft cutter and temple structures,it is easy to install, mechanical performance is more reliable;this can ensure a good weaving quality.

· Beating System

Beating cams are inbuilt in breast beam under fabric; thisdesign can increase the beating strength and workingbalance; more suitable for wide width and high cover factorfabrics. The aluminium alloy supports can ensure the reed agood linearity.

· Center Lubrication

Adopts independent motor to drive oil pump; all theimportant motion components are forced lubricated byindependent pipes.

· Electronic Take-up & Let-off

ETU & ELO is a standard configure of HY9000. Two servomotors are cotrolled by a compositive controlling box, whichensures let-off and take-up running synchronously. It is aguarantee for top quality production.

· Advanced Electronic Selvage System and Selector

Independent electronic selvage devices with step motors areinstalled front of heald frames, so all heald frames can be usedfor fabric weaving.Shed levelling time and design of selvagescan be set on microprocessor.The levelling time can be differentto the ground structure of cloth. All the setting can be madeduring loom running.

· High-speed Shedding Transmission

Electronic dobby is driven by super motor directly max canequip with 20 heald frames. cloth-fell motion is powerul Slow-motion and pick-finding is cotrolled by CPU and speed controlsystem.

· High-speed Insertion System

Insertion system adopts spatial linkages which are concentricwith cam shafts:insertion motion is driven by sector gears.This svstem is simple but stable,avoids most malfunctionsand extends the loom life.

· Low Power Consumption Motor

HY9000 adopts super start motor to drive machine directly with highertorgue, this is very suitable for high speed running. Change speed ontouching screen conveniently, Without main drive clutch and bet. dirctdmve is more powerful. this can reduce power consumption andmaintenance costMain motor drives pick-finding automatically. Duringreversing reed keep stop, on y hea d frames move.Main motor adoptsoi circulation cooling svstem which can ensure motors a long life.

· Fast-change Heald Frame

HY9000 can equip with not only normal heald frames withunderneath hooks but also adiusted heald frames. Heald framesand shedding devices can be connected quickly, it is easy toadjust the height of heald frames.

· Fast-change Beam & Cloth Roller

HY9000 can equip with fast-change beam system, this can savetime and increase efficiency.

· Overall Control, Advanced Speed Control System

HY9000 adopts10inch interactive touching screen friendkv interface, whichcan store plenty ofparameter settings of cloth. CPU controls all the functionsworking records.analyze and store al production data.Loom speedcan beset freely on operation interface. speed adiustable range isbigstart isfastbrake is accurate, can realize stepless speed change. This can reducevam breaks and prevent marks.With automatic weft switch function, evenweft breaks loom needs not stop Shedding levelling time can be set in acertain angle range, mechanical adjustmentisnotneededthis can well controlcloth quality, and also machine is easy to operate.

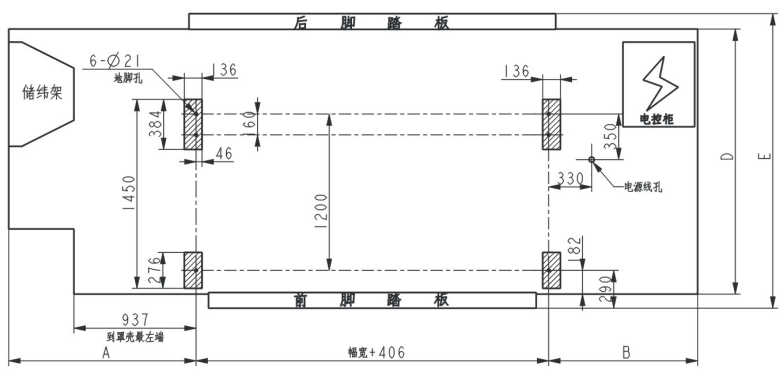

SPECIFICATION&DIMENSIONS

|

Item |

Spcification |

|

Reed width |

Nominal:190、210、220、230、250、340cm |

|

Width reduction(including false selvage):+6~-70cm |

|

|

Yarn range |

Spun yarn:Nm200-Nm3(Ne120-Ne1.8) |

|

Filament:10dtex~1500dtex |

|

|

With guide hooks,or free flight |

|

|

Warp yarn:sizing yarn,non-sizing yarn, twisted yarn,non-twisted yarn,mixed yarn |

|

|

Weaving speed |

Designed speed:750rpm |

|

Practical speed:500~650rpm(depend on width) |

|

|

Max insertion rate:1520m/min(depend on width) |

|

|

Weft |

Selector:1-8 color,same time may insert 2 picks |

|

Accumulator:electronic |

|

|

Weft cutter:mechanical |

|

|

Power |

Switched-reluctance motor speed control system |

|

Shedding |

Electronic dobby(max20 shafts) |

|

Electronic jacquard |

|

|

Beating |

Separate sley,both sides conjugate cam |

|

Insertion |

Both sides spatial four link insertion |

|

Let-off |

Continuous alternative current servo electronic let-off |

|

Single beam |

|

|

Beam flange dia:φ1000mm、中800mm |

|

|

Take-up |

Continuous alternative current servo electronic let-off |

|

Single beam |

|

|

Weft density:3~130 picks/cm (3~20、6~70、10~130) |

|

|

Selvage |

Leno device:electronic |

|

Selvage cutter:electronic(options:mechanical) |

|

|

Temple:LH&RH independent |

|

|

Lubrication |

Centralized+grease qun |

|

Stop motion |

Warp stop:6 or 8 lines electric touch-type |

|

Weft stop:electric piezoelectric sensor,with double pick function |

|

|

Others:auto stop for selvage yam |

|

|

Stop display:show stop reason on screen,multi- function 4 color lights |

|

|

Automatic |

Automatic stop at certain angle/low motion pick-finding/cloth fell compensation/warp tension adjustment,auto inspection/reset/fault indication |

|

Electric controlling |

Control:multiple function CPU control system.with functions of control,monitor,auto diagnose,data indication |

|

Display:touching screen with intercommunicaiton, immediate adjustment/parameter setting,programming |

Recommended Products

OEM/ODM Processing Services

Here, we provide a convenient online inquiry service. You only need to briefly fill in the following information, and our sales team will provide you with a detailed quotation within 24 hours.

Whether your needs are a single product or a complete set of customized solutions, we will provide tailored quotations and technical support according to your specific requirements.

GET A CUSTOMIZED QUOTE

Here, we provide a convenient online inquiry service. You only need to briefly fill in the following information, and our sales team will provide you with a detailed quotation within 24 hours.

Whether your needs are a single product or a complete set of customized solutions, we will provide tailored quotations and technical support according to your specific requirements.